Water vapor separation vacuum pump

Product description:

The water vapor separation vacuum pump vacuum equipment includes a centralized control room, a high-power vacuum pump, and a water vapor separation tank. The water ring vacuum pump is used to change the gas capacity in the water vapor separation tank to form a negative pressure. Through controllable negative pressure adjustment, a stable negative pressure difference is formed in the reinforcement area controlled by the water vapor separation tank.

Service hotline:

136 0005 0009

Consult now

Equipment Introduction

The water vapor separation vacuum pump vacuum equipment includes a centralized control room, a high-power vacuum pump, and a water vapor separation tank. The water ring vacuum pump is used to change the gas capacity in the water vapor separation tank to form a negative pressure. Through controllable negative pressure adjustment, a stable negative pressure difference is formed in the reinforcement area controlled by the water vapor separation tank. The negative pressure difference is used to discharge the water and gas mixture in the soil that needs to be reinforced into the water vapor separation tank, By utilizing the height of the water vapor separation tank, water and gas are naturally separated, forming gas above and water below. Finally, the gas is discharged from the exhaust port of the vacuum pump connected to the upper interface of the water vapor separation tank, and the water is discharged from the jet pump connected to the lower interface of the water vapor separation tank. This not only achieves the purpose of soil consolidation, but also improves vacuum pumping efficiency, reduces electricity consumption, and reduces the overall construction cost of vacuum preloading.

Equipment characteristics

1. Invention patent (patent number: ZL 2015 1 0083730.7).

2. Discharge the muddy water into the upper chamber of the vacuum negative pressure chamber, and control the negative pressure inside the upper chamber to prevent the generation of water vapor and reduce the vacuum degree. The drainage and pressure relief controller relies on its own gravity and the buoyancy generated by being placed in the water environment to automatically open and close the water hole and pressure relief port during the drainage process for automatic drainage, and the water vapor separation is automatically completed.

3. Effectively prevent water vapor mixture from damaging the vacuum environment in the vacuum negative pressure chamber. Ensure that the vacuum negative pressure in the vacuum negative pressure chamber is between 85kPa and 90 kPa, and at this pressure, the boiling point of water is between 33-46 ℃. It can effectively prevent energy loss caused by water turning into steam at room temperature.

Compared with traditional small-scale jet vacuum pump technology, it has significant improvements in performance such as pumping rate, ultimate vacuum, pumping volume, and compression ratio. It has the advantages of high efficiency, small footprint, convenient construction, simple operation, high concentration, and high safety.

5. Compared to traditional jet vacuum equipment, it saves more than 50% of energy consumption. Only two 15kw water vapor separation devices are needed to complete the task of 30 7.5kw vacuum jet pumps working simultaneously.

6. Effectively improve the efficiency of soft foundation treatment, save costs, improve quality, shorten construction period, and reduce energy waste.

Shengzhou focuses on the maintenance, repair, leasing, and sales of soft foundation treatment machinery, with strong professional technical strength, complete mechanical equipment support, advanced management methods, controllable production process, and excellent reputation. At the same time, we focus on technological research and innovation within the industry. We have multiple patented technologies in terms of technological breakthroughs, technological innovation, research and development, including 5 invention patents.

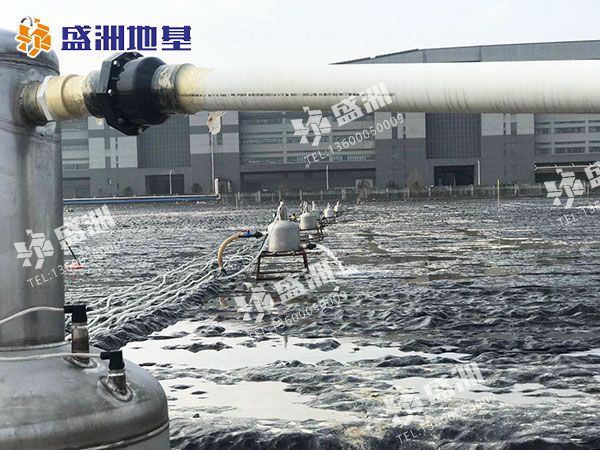

Construction site drawings