Prefabricated Vertical Drain (PVD) - commonly used geotechnical materials for soft foundation treatment

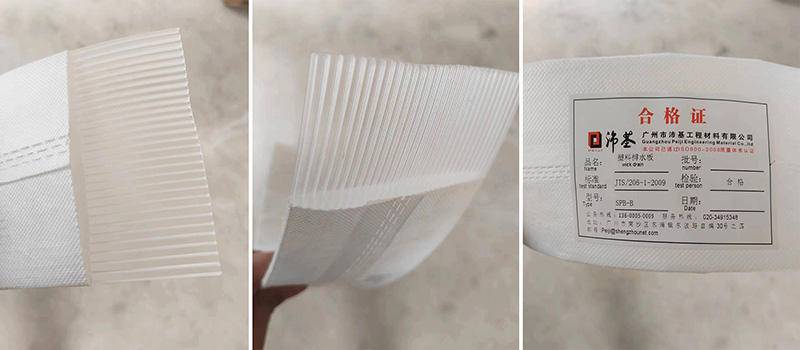

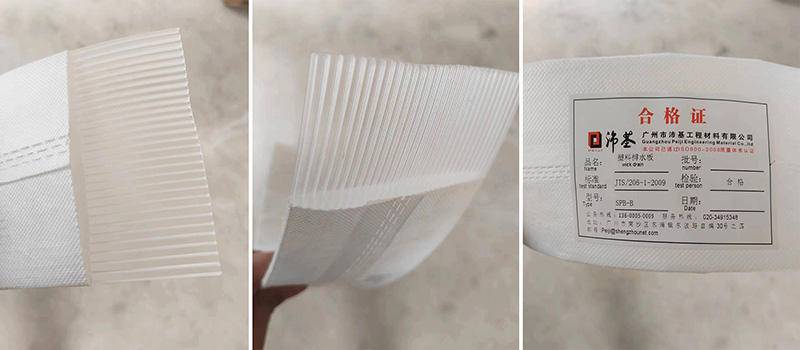

Prefabricated Vertical Drain (PVD),Plastic drainage board, also known as plastic drainage belt, is a new type of geopolymer material used for soft soil and soft foundation treatment and reinforcement. It is divided into SPB-A, B, C, and D model series. The middle of the plastic drainage board is an extruded plastic core board, which is the skeleton and channel of the drainage belt. The core board is mixed with polypropylene (PP) and polyethylene (PE), and its cross-section is parallel cross shaped. The cross-sectional size of the plastic drainage board is 100mm wide and 3.5-8mm thick, Two loaves are made of non-woven geotextile as the filter layer, and the filter membrane is made of long fiber hot rolled non-woven fabric. The core belt serves as a support and discharges the water that seeps into the filter layer upwards.

The working principle of plastic drainage board: The plastic drainage board is inserted into the soft soil foundation using a plug-in machine. Under the action of the upper preloading load, the water in the gaps in the soft soil foundation is discharged from the plastic drainage board to the sand layer or horizontal plastic drainage pipe laid on the upper part, and discharged from other places to accelerate the consolidation of the soft foundation. Plastic drainage board reinforcement of soft soil foundation has the advantages of good reinforcement effect, fast construction speed, and low cost, so it is widely used in soft soil foundation reinforcement engineering.

The working principle of plastic drainage board: The plastic drainage board is inserted into the soft soil foundation using a plug-in machine. Under the action of the upper preloading load, the water in the gaps in the soft soil foundation is discharged from the plastic drainage board to the sand layer or horizontal plastic drainage pipe laid on the upper part, and discharged from other places to accelerate the consolidation of the soft foundation. Plastic drainage board reinforcement of soft soil foundation has the advantages of good reinforcement effect, fast construction speed, and low cost, so it is widely used in soft soil foundation reinforcement engineering.

Sunzo Company produces various specifications of plastic drainage boards, and the prices may vary slightly due to different specifications. For more information, please feel free to contact us by phone!

construction technology

1. After laying the lower layer of sand cushion, measure and determine the control corner points of the laying area, set out the laying points of each plastic drainage board, and mark them. According to the marking of the laying plate, position the insertion machine.

2. Put the plastic drain plate through the casing of the board inserting machine, and then go out from the lower end of the casing to connect with the special pipe shoe. After the connection is completed, adjust the verticality of the board inserting machine casing to meet the requirements of relevant specifications.

3. Insert the insertion machine casing (along with the pipe shoe and plastic drainage board) into the formation, and when the drainage board is inserted to the design depth, pull out the insertion machine casing, and the drainage board is fixed at the bottom of the hole.

4.After inserting and punching the drainage board, pull out the sleeve of the insertion machine, cut the drainage board, and the length of the plastic drainage board beyond the hole should be able to penetrate into the sand cushion layer no less than 500mm. The reserved section should be bent and buried in the sand cushion layer in a timely manner.

5. Check the position, perpendicularity, installation depth, exposed length, etc. of the drainage board and ensure that they meet the requirements of the specifications before moving the machine. After inserting the plastic drainage board, before the hole shrinks, timely backfill with medium coarse sand to prevent soil and other debris from falling into the hole, and then lay the upper layer of sand cushion.