Soil Pre-Compression

Soil Pre-compression is one of the ground improvement technique which compresses the ground under an applied pressure before placing or completing the structural load. Pre-compression is performed in following two ways:

1.Ground precompression is achieved by pre-loading, which requires placement and removal of earth, water, or some other dead load, before construction, similar in weight to the final load.

2.Surcharging is where the stress intensity from the pre-loading is greater than the intensity from the final loading.

Ground Improvement with Soil Pre-Compression

Pre-compression of ground is used to induce settlements that have three recognizable phases: immediate, primary consolidation and secondary consolidation (or creep). In a loose fill with large voids, the potential for immediate settlement can be a very high proportion.

Pre-loading and surcharging Soil

Pre-loading soil & surcharging usually involve placing an earth fill over quite a large area or over several areas within one site. For full economy, the fill should be reused. Materials which are used to form the load can be earth-fill or rock-fill, water or any other easily transportable and available bulk fill. Once the settlement under the pre load is completed, the preload is removed is removed and the construction of the structure is started.

Preloading & Ground Improvement with Soil Pre-Compression in Singapore

By the use of vertical sand drains the consolidation process can be increased which reduces the time of pre loading. In general the area of the final structure is less than the preloading area because the stresses produced at any depth in the foundation soil are uniform. It should be equal or greater than the final stress produced at that location.

During the pre-compression method, control over the following aspects is necessary:

● The rate of filling

● Over pore pressure responses in the foundation soils

● Lateral movements in the foundation may all be necessary

Limitations of Pre-loading & Surcharging:

● insufficient time available to achieve the required compression or pore-pressure dissipation

● Excessive lateral deformation of the pre-compression fill, often because of the transmission of high pore pressure

● Inadequate factor of safety against shear failure when the structure is complete. It is essential to check stability at this stage.

● Post-construction settlements may be greater than expected.

Hence for these reasons, the ground investigation has to be very thorough and a field trial loading is essential. The main constraint for saturated clay soils is the available time. When loose, open textured fills are pre-compressed, a great deal of the settlement takes place very quickly, and the available time should not be a constraint. The pre-compression fill should either be free draining or a drainage layer is placed first if it’s on an impermeable ground. It should be noted that loose, clean sands are not densified very much by pre-compression.

One of the best merits of this technique is that it is almost free of noise and vibration problems that are faced in other technique. Hence it is preferred in those places where environmental restrictions are involved.

Preloading & Ground Improvement with Soil Pre-Compression in Singapore

Soil Pre-Compression | The construction process or sequence of preloading is as follows:

site cleaning and leveling → laying of sand cushion layer → layered filling of earth and rock → preloading → unloading → construction inspection.

site cleaning and leveling → laying of sand cushion layer → layered filling of earth and rock → preloading → unloading → construction inspection.

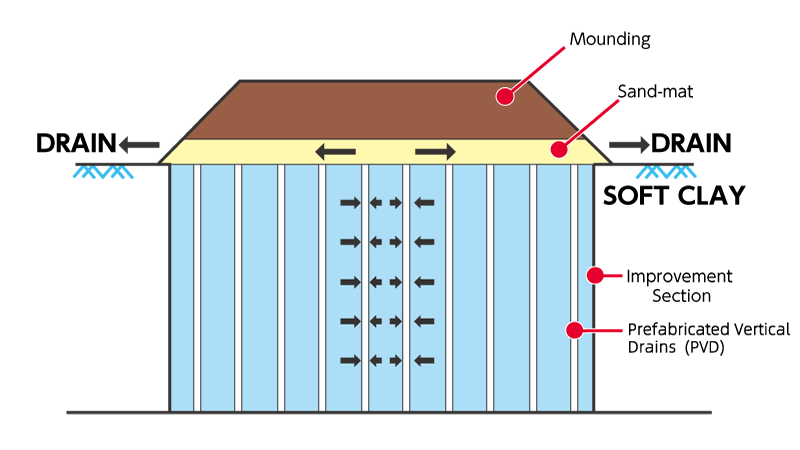

To accelerate the rate of primary consolidation in low permeability strata, prefabricated vertical drains (PVD) or sand drains can be installed to significantly shorten the drainage path length and take advantage of the possible higher horizontal soil permeability. The PVD drains typically comprise a corrugated core through which water can flow, with a permeable geotextile outer cover. The drains are usually installed using a rig mounter push in mandrel. Sand drains are commonly formed by drilling a small diameter borehole and filling it with a clean coarse sand.

SUNZO has significant experience with these methods and can undertake pre-load and surcharge design, incorporating embankment height and PVD/sand drain spacing design and specification, to optimise the surcharge solution.

Our design solutions incorporate details of the anticipated construction timeframe, the post construction settlement tolerances and detailed assessments of the surcharge fill and in-situ material characteristics. We also provide monitoring specification, installation, measurement, processing and interpretation services to ensure correct implementation of the design.

Characteristics of surcharge preloading

By preloading, shallow and uneven settlement can be reduced. This method fully utilizes the strong structural and low permeability characteristics of soft soil, and the settlement rate is also easy to converge, meeting design requirements.

The preloading method is effective and suitable for the foundation treatment engineering of airport and port terminals on soft soil foundations. The construction materials and equipment for preloading are relatively simple, the construction operation is convenient, and the engineering application is relatively mature.

The amount of earthwork and stonework that is overloaded and stacked can be used for backfilling in the soil surface area, which can reduce the cost of transporting and purchasing fillers.

In coastal areas, in order to meet the requirements of flood control and drainage, the designed filling height is not large, and the filling load is less than the bearing capacity of the foundation, so there is no problem of slope stability.

The requirements for the construction period of preloading are relatively loose and suitable for engineering projects with tight schedules.

Any commercial or operational questions? Any technical questions? Please contact

E-mail : sunzo-market1@shengzhounet.com

Contact Person: Mr.Wong

Mobile Phone: 0086-136 0005 0009

WhatsApp: 0086-150 1309 3207

WeChat: 0086-150 1309 3207