Prefabricated Vertical Drains (PVD) Installation

Prefabricated Vertical Drains (PVD),also known as Wick drains are prefabricated geotextile filter-wrapped plastic strips with molded channels. These act as drainage paths to take pore water out of soft compressible soil so it consolidates faster.

In doing this, it prevents intrusion and clogging of soil particles. Prefabricated vertical drains have remarkable flow discharge capacity and are usually coupled with surcharging to accelerate preconstruction soil consolidation.

They are installed in soft clay layers which cater to the accelerated consolidation and gain in shear strength.

While penetrating soft clays, the pore water pressure is increased more rapidly thereby reducing the preloading time, increasing water dissipation, shortening pore water travel distance, and compressing soil voids.

The pressure exerted in the pore water can influence the drain flow. In this case, pore water will flow sideways to the nearest drain, as opposed to vertical flow to an overlying or underlying drainage layer.

Quality Control in Prefabricated Vertical Drains Installation

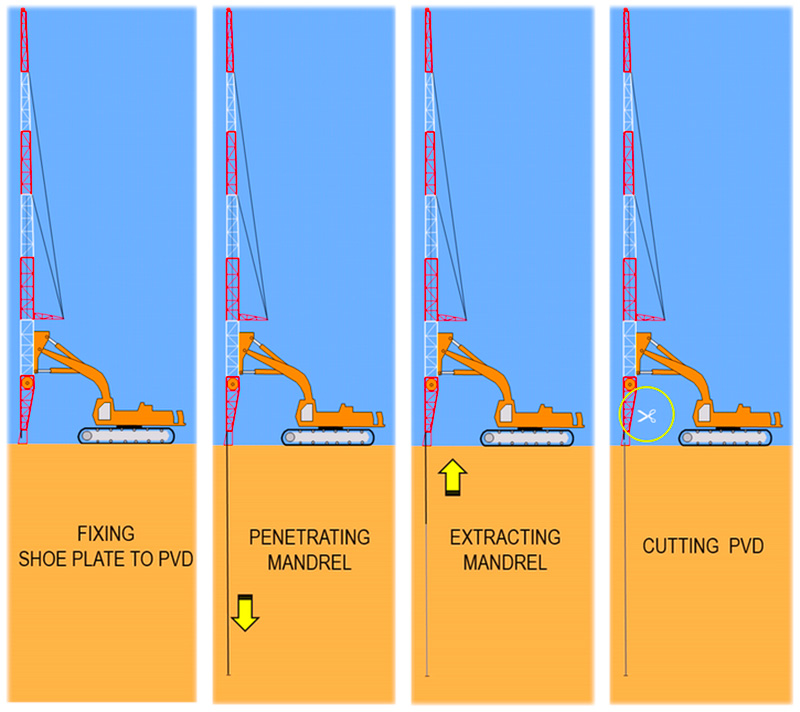

Detailed Procedure of Installation of PVD

1. Marking of locations to be installed with PVD in accordance with the construction drawing. The PVD shall be installed in form of square net and placed by the distance of design drawing and designed depth from the surface of sand mat layer as specified.

2. Setting PVD driving machine at right location in accordance with the designed layout.

3. PVD shall be installed to the mandrel, operating the lead of the mandrel to the location of PVD to be installed.

4. Attach anchor plate to the end of PVD with the fold up of PVD and fastened by steel pin.

5. Insert the mandrel with PVD to the designed depth. When PVD is already installed, the mandrel is pulled up (concurrently the anchoring end shall keep PVD in the ground). When the mandrel is completely pulled up, PVD shall be cute by scissors leaving 30cm over the top of sand mat. The process of installing PVD shall be started in a sequential manner to the subsequent locations.

6. Overlap joint of PVD is at least 30cm and fastened.

7. The Contractor shall correctly record each installation, quantity of PVD, coordinate of grid and length of PVD.

8. After the installation has been completed, the Engineer shall be invited to check and subsequent items shall only be carried out after getting the approval from the Engineer for the above work.

9. All other requirements for installation of PVD shall be observed by the Contractor in accordance with the specifications.

10. Remove or replace PVD improperly installed or damaged as directed by the Engineer.

11. After installation 30cm of PVD above surface of sand mat will be folded into the sand mat by workers.

Characteristics of PVDs

PVDs are meant to serve 2 basic functions:

1. The plastic core serves as a longitudinal flow path along the drain.

2. Filter jacket performs two functions: allows water flow into the core; prevents soil particles from penetrating.

Typical Applications PVDs

Prefabricated Vertical Drains installation can be successfully applied in various projects typically used as ground improvement system, including:

• Construction of road, airport, ports, railway, and embankment

• Industrial projects

• Land reclamation projects

Quality Control in Prefabricated Vertical Drains Installation

• Maintain verticality by using Mandrel with adequate stiffness.

• Minimize soil disturbance by using the appropriate size of Mandrel and anchor plate.

• Ensure to check verticality during installation.

• Avoid significant bending by applying the appropriate penetration rate.

Quality Control Test For PVD Materials

• The density of filter fabric

• Apparent opening size

• Burst strength

• Grab tensile strength

• Puncture resistance

• Discharge capacity (plain and triaxial)

• Trapezoidal tear strength

The Bottom Line

As geosynthetics continue to improve, installation monitoring techniques become more sophisticated.

In fact, quality control of PVDs has also improved with the use of electronics to the installation equipment.

Any commercial or operational questions? Any technical questions? Please contact

E-mail : sunzo-market1@shengzhounet.com

Contact Person: Mr.Wong

Mobile Phone: 0086-136 0005 0009

WhatsApp: 0086-150 1309 3207

WeChat: 0086-150 1309 3207