Drainage Consolidation

Drainage Consolidation

Water soil improvement

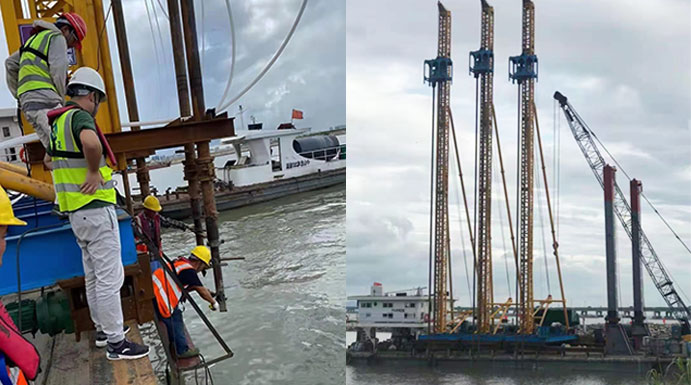

On water and offshore foundation treatment, the foundation treatment and reinforcement of offshore construction projects such as reclamation ports, offshore airports, artificial islands, etc., are much more difficult than on land construction due to the multiple effects of uncertain factors such as seawater tides, wind waves, and ocean weather. In order to effectively solve the problems of offshore soft soil foundation treatment and maintenance, compared to traditional methods, new technologies such as PVD plastic drainage boards on water and deep cement mixing piles on water are adopted, The construction cost is lower and the impact on the marine environment is less, making it one of the effective methods for soft foundation treatment at sea.

Construction Technique

Water PVD technology

Water PVD technology

The water PVD (plastic drainage board) engineering ship has two PVD (plastic drainage board) engineering ships, which use a shallow draft flat boat and a gantry type amphibious insertion machine for insertion. It adopts advanced GPS positioning and can meet the requirements of engineering design for insertion depth and spacing. The hard soil layer has strong penetration force and construction efficiency. The cumulative construction of water PVD (plastic drainage board) has reached 35 million meters, which can meet the requirements of offshore construction and strong anti surge It has stability, safety, and sustainability.

View detailsWater mixing pile technology

Water mixing pile technology

The underwater deep mixing pile construction method, mixing pile engineering ship, underwater soil cutting and mixing, accurate injection of cement slurry, exchange of high and low slurry nozzles, environmental protection treatment system, intelligent control construction and other technologies are integrated, mastering the intelligent construction core technology of engineering ship mobile GPS positioning system, leveling system, cement slurry mixing and grouting system, drilling and lifting pile system, and other intelligent construction systems. It is a pioneer in domestic technology.

View detailsWater based vibroflotation technology

Water based vibroflotation technology

The above water vibroflotation technology and the vibroflotation process for filling materials meet the quality requirements of construction pile position, verticality, and other parameters. The vibroflotation device is accurately positioned underwater and synchronized with multiple vibroflotation devices to ensure balanced stress on both sides of the pipeline during the vibroflotation process, ensuring quality assurance, significantly reducing cost and shortening construction period.

View detailsWater PVD engineering ship

Water PVD engineering ship

The water PVD (plastic drainage board) engineering ship has two PVD (plastic drainage board) engineering ships, which use a shallow draft flat boat and a gantry type amphibious insertion machine for insertion. It adopts advanced GPS positioning and can meet the requirements of engineering design for insertion depth and spacing. The hard soil layer has strong penetration force and construction efficiency. The cumulative construction of water PVD (plastic drainage board) has reached 35 million meters, which can meet the requirements of offshore construction and strong anti surge It has stability, safety, and sustainability.

View detailsDeep mixing pile on water

Deep mixing pile on water

The above water DCM construction method integrates multiple technologies such as underwater soil cutting and mixing, accurate injection of cement slurry, exchange of high and low slurry nozzles, environmental protection treatment system, and intelligent control construction. It masters the core intelligent construction technologies such as engineering ship moving positioning system, leveling system, cement slurry mixing and grouting system, drilling and lifting pile system, breaking the monopoly of Japan and South Korea in this field, and is a pioneer in domestic technology. We have 4 DCM engineering ships and 15 onshore DCM pile drivers.

View detailsCore Competitiveness

Possess multiple new invention patents

Intelligent control construction, environmental protection treatment system, and multiple new invention patents core construction technologies

Efficient construction technology and construction quality

Adopting GPS global positioning system and self-developed multifunctional drainage plate construction automatic recorder, it has strong penetration force in hard soil layers, more efficient construction, strong resistance to surges, stability, safety, and sustainability during offshore construction.

Own a complete set of construction equipment

12 insertion machines and 8 sets of clay mixing pile machines

We have 2 PVD engineering ships, over 800 sets of vacuum preloading water and gas separation equipment, vacuum pumps, various models of plastic drainage board materials, and one-stop service for equipment and material construction.

PROJECTS