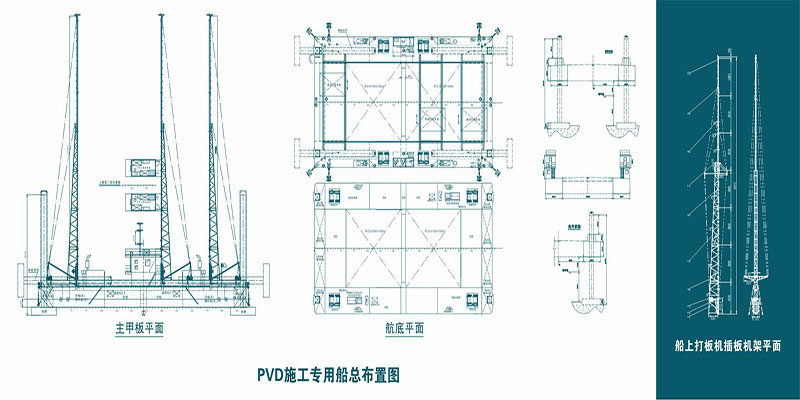

Water PVD (drainage board) engineering ship

1. New invention patent (201720184125.3)

2. PVD water construction special vessel that meets the construction environment of offshore soft foundation treatment

3. Fast lifting and autonomous sliding construction, effectively improving construction efficiency and quality, shortening construction period, and reducing costs

4. Two sets of fixed pile anchors and two sets of steel wire rope anchors are used, and four hydraulic piles with automatic lifting are used to support the entire ship 50-100cm during construction. It has strong resistance to surging waves in monsoon sea conditions, and has stability, safety, and sustainability

5. Adopting a new type of friction board insertion machine with ultra-low center of gravity, the frame can lift and lower itself, meeting the time and height limit operation in special areas. It can solve mechanical faults and PVD return at any time, without the need for high-altitude operation. In the event of a typhoon, safety protection is more effective

6. When the design pressure standard is exceeded, vibrating drainage board construction machinery can be attached

7. Using the GPS global positioning system and jointly developing a multifunctional drainage board construction automatic recorder, the coordinates, installation depth, return situation, pressure, and frame verticality of each drainage board are comprehensively monitored and recorded

8. Use an underwater drainage plate automatic cutter (using the horizontal knife method for underwater cutting)

9. Advantages: It can meet the requirements of PVD (plastic drainage board) construction on water, has strong resistance to surges, and has stability, safety, and sustainability.

Construction process

(1) Positioning: Based on the design plan of the water plug-in board and the single ship construction scope of the plug-in board ship, determine the coordinates of the edge and corner points of each ship's installation area. The dedicated plug-in board ship is arranged parallel to the longitudinal axis of the embankment, and is positioned using a set of GPS systems and base stations on board, according to the calculated coordinates of the positioning points. The professional plug-in ship GPS system is connected to the measurement base station, and under the control of the ship's computer system, the ship's moving anchor machine is started to accurately determine the location of the ship in the construction area, and the pile driver is moved to the construction position;

(2) Move the ship for positioning, and the positioning deviation should not exceed ± 30mm, and make positioning records.

(3) Set up ship positioning, check the accuracy of fixed benchmarks, ropes, and plates. Move the installation frame so that the casing is aligned with the board position, and the depth of installation on the casing should be clearly marked with a length (with red lines drawn per meter).

(4) Calculate the sinking depth of the pile pipe and the length of the plastic drainage board, and pre cut the plastic drainage board, leaving an exposed area of no less than 20cm. Thread the pre cut drainage board into the sleeve, and cut the length of each drainage board according to the design length.

(5) Install the pipe shoes. Bend the end of the drainage plate that has already penetrated into the sleeve, insert the opposite end into the sleeve, and insert the pipe shoe into the plate ring. Then tighten the drainage plate upwards, so that the plate ring of the drainage plate is embedded with pipe shoes into the duckbill type pipe end at the bottom of the sleeve (the bottom edge of the pipe should be about 1cm lower than the bottom of the drainage plate), and movable pipe shoes can also be used to fix the plate end.

(6) According to the construction location, timely measure the underwater depth with a water gauge and keep records. The depth of the drainage board installation+the depth of the water level (calculated based on the current tide level)+the distance from the water surface to the operating platform. Water level measurement is crucial. If the measurement is not accurate, the drainage board installed will either be exposed too long or too deep.

(7) Sink the casing, start the vibration hammer and set it to the design elevation. Look for the red mark on the sleeve.

(8) Pull out the pile pipe, move the pile frame, and reinstall the drainage board, following this procedure.

(9) Cut the plastic drainage board. (or using pre cut construction methods)

(10) Check and record.

(11) Move the scaffolding to align the sleeve with the next board position.

(12) After the plastic drainage board of each ship position is installed, the anchor is shifted and the construction of the next ship position is carried out.